Durability & Safety Our focus is on sustainability.

In the animal world, whales beat all life span records. Greenland whales can live up to more than 200 years. Gray whales, belonging to the Mysticetes, can live up to 50-70 years of age.

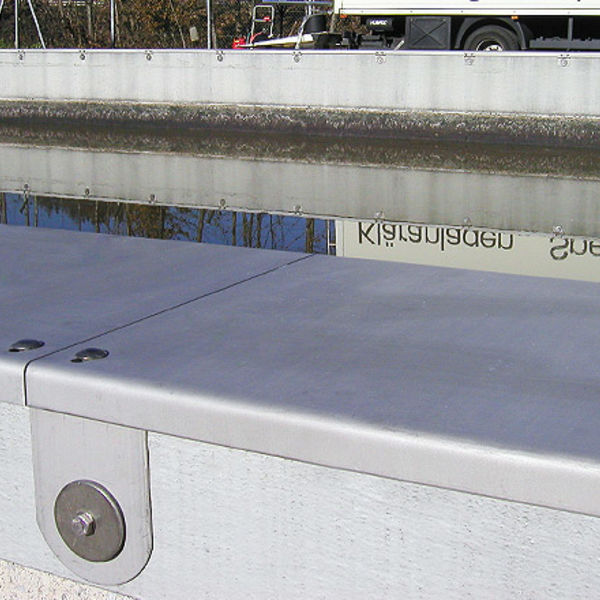

Our products too are renowned for lasting much longer than average. For over 35 years, and on more than 3,000 water treatment tanks, Krumme scraper tracks have been providing operational durability rates significantly higher than those of concrete tank crests that are excessively stressed. With our innovative systems, we have repeatedly set new parameters. In terms of robustness and resistance, in Europe, our scraper tracks are unequalled.

Scraper tracks for new constructions and for overhauls Examples of Krumme works

Examples of circular tanks

Examples of rectangular tanks

Scraper tracks – everything you need to know State-of-the-art concrete base & installation of stainless steel elements: perfect synergy

In wastewater treatment plants, scraper tracks are concrete elements subjected to tremendous chemical and mechanical strain. If inadequately protected, in the long run even correctly processed concrete is incapable of resisting this kind of stress. Damage such as spalling, cracking or the collapse of thinner structures often occurs just a few years after becoming operational.

With concrete tank crests, humidity, freezing temperatures and the continuous passage of the scraper carriage inflict constant wear and tear on the surface.

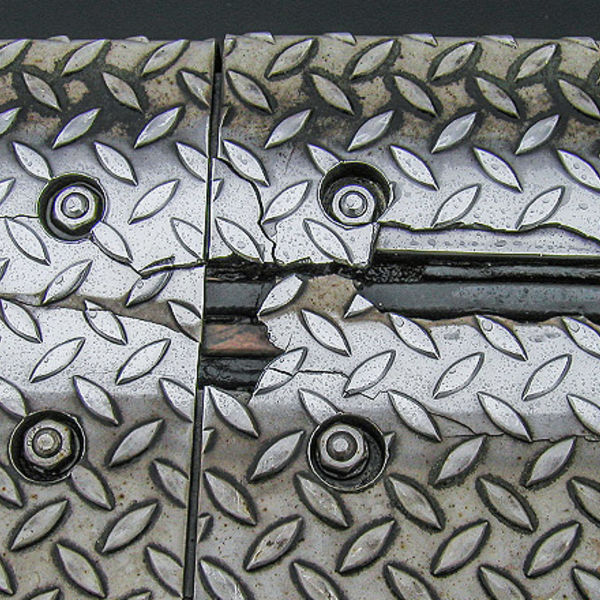

The weak point of any concrete structure are unprotected expansion joints that can be attacked by water and freezing. After a short time, the scraper wheels will show the first signs of damage.

Up until the 1990’s, plastic material coverings were preferred for preventive protection and for revamping scraper tracks. The different thermal expansion and waterproofness values of the plastic materials, however, were often the cause of a shorter operational life of these elements too.

The strength of a scraper track is equivalent to that of the base on which it is mounted. A tank crest remains unaltered over time only if the concrete of the base is adequately renovated. We eliminate any damages at their source instead of covering them up.

For over 35 years, Krumme tank crest linings have been the most economically convenient and long-lasting solution to this problem because they can also withstand the extreme stresses generated by the scraper carriage.

Only the combination of a stable concrete base with the proven Krumme scraper track offers excellent stress absorption. The guaranteed result is a reliable and wear-resistant scraper track that also effectively and permanently protects the tank crest from weathering. No other scraper track system on the market is capable of offering the same level of strength and safety.

Durable and high-performance stainless steel

In water treatment facilities, only at least class 2 resistance material should be used. This also applies to stainless steel, that should be minimum grade 1.4301 (AISI 304).

Today, instead, materials such as aluminium or other metals are still being proposed for their better heat conductivity parameters or for their lower cost. The problem with these materials is that, in presence of great strain, they resist the scraper carriage stresses for only a few years. The metal becomes fragile and then cracks and breaks easily. Even the galvanised steel rails of the guides soon develop mechanical damage and rust. Initially, all this only affects the metal’s appearance, but then starts interfering with the scraper’s action due to the increase in traction.

Not even rigid stainless steel coverings are suitable, because the vibrations and the material’s expansion soon cause severe damage.

If the guide rails are made of galvanised steel, the material wears down and rusts, and signs of corrosion appear underneath the tank crest. The rigid seat of the rails also stresses and causes damage to the concrete.

Not even rigid stainless steel coverings are suitable, because the vibrations and the material’s expansion soon cause severe damage.

If the guide rails are made of galvanised steel, the material wears down and rusts, and signs of corrosion appear underneath the tank crest. The rigid seat of the rails also stresses and causes damage to the concrete.